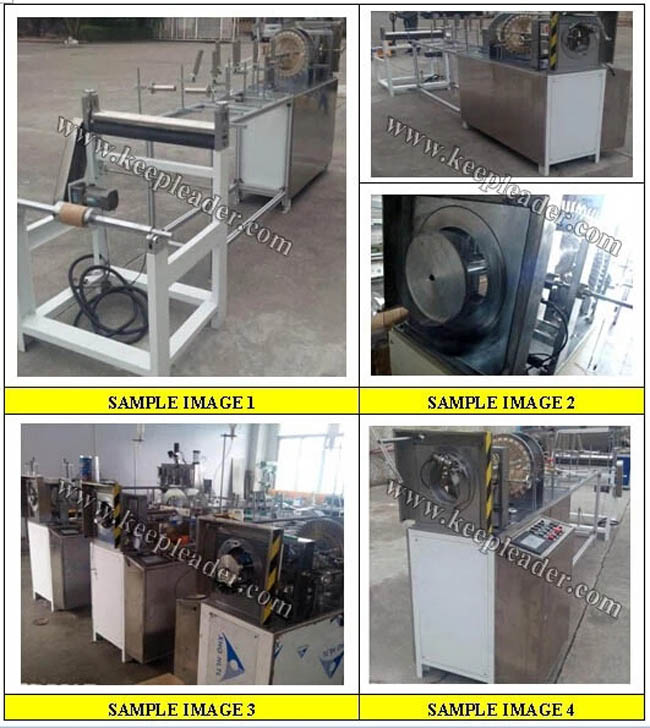

Plastic Cylindrical box forming machine of transparent cylinder auto making machine

Application:

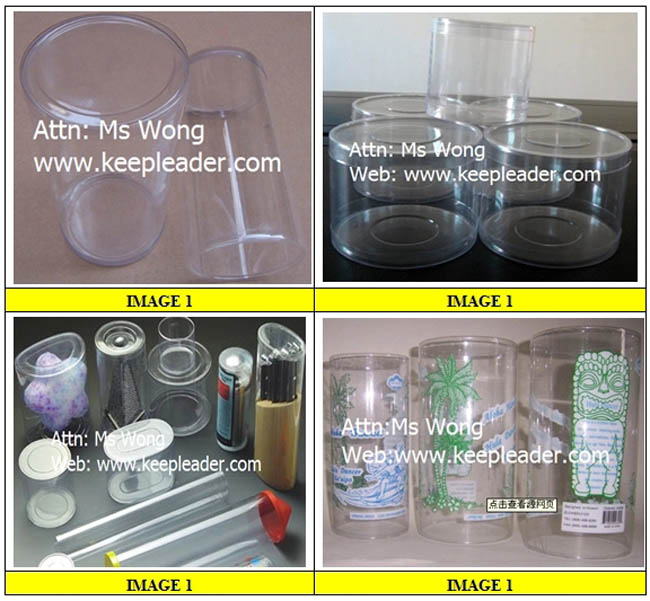

Plastic cylindrical box forming machine is automatic plastic rolled sheets forming to make cylindrical box, this machine is just to make two end open tubes at its side sealing by ultrasonic welding or gluing, also can coupled with hole punching unit to make mounting holes in making carrying cylindrical box, the plastic rolled sheet can be clear, or printed PVC, APET, PETG, PP and etc. the manufacturer can choose KEEPLAEDR’S plastic cylindrical box bottom, lid forming, cutting machine and bottom sealing machine to composite a whole production line, often used in out packing of candy, gifts, toys, stationery, umbrella, fishing tools

Parameter

| Model | KLY-200 | KLY-300 |

| Cylinder Diameter | 40mm–200mm | 40mm–300mm |

| Cylinder Length | 10mm-4000mm | 10mm-4000mm |

| Materials Thickness | 0.15mm-1.0mm | 0.15mm-1.0mm |

| Control System | PLC | |

| Overall dimension | 4200mm*880mm*1500mm | |

| Ultrasonic Welding | :50pcs/m (according to cylinder length: 100mm/pc) | |

| Gluing | 60pcs/m ( according to cylinder length: 100mm/pc) | |

Characteristics

The feeding speed can reach 30 meters per minute

Simple operation and convenient maintenance, one operator is ok

PLC controlling system, build in servo motor driven feeding unit

Cutting and trimming edge completed in one cycle

Adhesive spraying device to glue the overlap evenly, no scratches and looks clear

The cylinder length is optional, the cylinder diameter can change though different size molding

Ultrasonic sealing and gluing in one machine

Full automatic proves from rolled sheet to separated cylinder in rated size

With Photo electronic counter