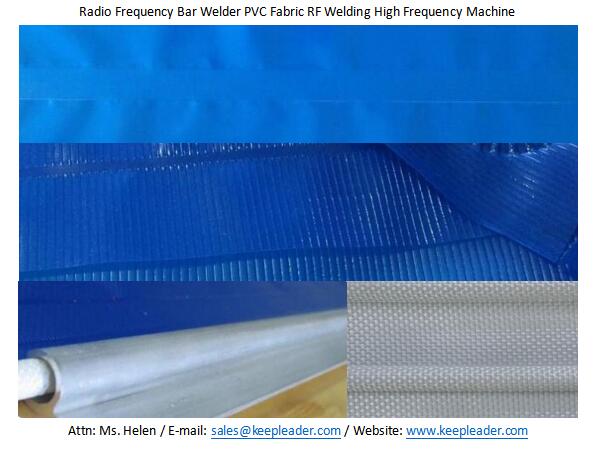

Radio Frequency Bar Welder PVC Fabric RF Welding High Frequency Machine for Tarpaulin_Tent_Awning_Liner_Banner Seam Heat Sealers

Radio Frequency Bar Welder PVC Fabric RF Welding High Frequency Machine

01;Application

Radio Frequency Bar Welder PVC Fabric RF Welding High Frequency Machine is the industry’s most versatile dielectric bonding sealer available on the market in flexible products made of thermoplastic in membrane structure, for example,designed for the production of tarpaulins, tents, truck tarps, high speed door, shading, covering, lining,singing, banning, insect screening, protective packaging, stretch ceiling, roofing and air, liquid supporting, and other innovative flexible parts contained PVC, PU, PETG, PTFE, best for: Aerospace, athletic mats, awnings, billboards, blinds, clear span buildings, containment booms, conveyor belts, agriculture curtains, gymnasium curtains, roller doors, evacuation slides, flexible storage tank/bladders, Geo-membrane/liners, greenhouses, mattresses. Pergolas,pool covers, pools,inflatables, screens, shades/tension structure, signs,banners.tarpaulins, tents,canvas

02: Parameter

| Radio Frequency Bar Welder PVC Fabric RF Welding High Frequency Machine | ||

| Model | KLR-12KWF | KLR-15KWF |

| Power Output | 12kw | 15kw |

| Power Input | 20kva | 25kva |

| HF Frequency | 27.12MHZ+-0.5% | 27.12MHZ+-0.5% |

| Power Source | 380v,50hz,3P/220V,60HZ,3P | |

| Trough Depth | 115~150cm/optional | |

| Rectifier | Silicone | Silicone |

| Oscillation Tube | E3130RB | 8T85RB |

| Max Pressure | 800kgs | 1000kgs |

| Operation Mode | Pneumatic | Pneumatic |

| Electrodes Gap | 100mm | 100mm |

| Active Horn | 100mm | 100mm |

| Upper Electrode | 100*800mm | 100*1000mm |

| Lower Electrode | 400*1000mm | 400*1200mm |

| Max weldable area | 2000mm2 | 3300mm2 |

| Welding Time | 0.01~9.99s adjustable | 0.01~9.99s adjustable |

| Net Weight | 800kgs | 1100kgs |

| Overall Dimension | 1700*1400*1800 | 1750*1580*1800 |

03: Features and benefits

HF/RF emission protection

Anti-crush electrode safety motion system

Customized electrode available for versatile production

New generation stable and efficient HF Power generator

Universal usage for PVC,PU,TPU,reinforced technical textiles

Easily change dies with to exert versatility in size, shape and profile

Deep material trough to go through aligned fabric in position handling

Auto-tuning for steady HF/RF power feed to assure consistent welds

Foot pedal operation, more convenient to control the welding process

Customized work table dimensions, electrode holder dimension, tooling

CSingle line or two lines welding, its length can be ordered as special need

frame or G frame welded steel structure with integrated HF/RF generator

Easier material placement and batter visualization of weld with built in laser guiding device

Manual, semi-automatic and automatic operation for convenient debugging, operation

Swing arm operation panel with touch screen and program logic control is available

The preheated electrode bar is equipped to assist on non-HF/RF weldable fabrics

Length, width and radian of welding area can be adjusted by change welding electrode

European-model square high frequency vibration box is more reliable and table in output

Can be used as freestanding for welding production or as a supplement to large system

Laser guide projectors to project laser lines for quick material guidance on the work table

04: Salient Features

Anti-spark protection: when spark occur, the high sensitiveness spark protect electric system, cuts power immediately to protect mould and material

Jamming prevention device: high frequency welding machine equipped with frequency stabilizer and high frequency magnetic leakage suppressor, this device provide leakage of electron magnetic radiation to avoid jamming other electrical instruments such as television and radio etc

Safety device: when the current exceeds this limit, the overload relay work automatically to protect oscillation tubes and rectifier, frequency deviation caused by wrong operation is also prevented

Easy tuning and special protection circuit: welding time and heating time is adjustable according to material thickness and size

Easily adjustable tuner: high frequency welding machine output power can be adjusted at the tuner according to electrode size and material thickness, in addition, other control devices and special electrical circuits have cut down required welding time considerable to raise the machine productivity

Adjustment for the distance on the machine head: high frequency welding machine adjust the distance on the machine head if practical as the size of mould and height are different, save working load while processing accuracy

Radio Frequency Bar Welder PVC Fabric RF Welding High Frequency Machine has theory of: under the effect of the high frequency electric field, the positive and negative charges of the substrate to be heated displace to form electric pole polarons, the polarons polarize repeatedly to cause the molecules to produce the intense friction to give heat out, the electric field energy absorbed by the substance changes into heat energy to realize the purpose of heating which cause the middle-melt state of plastic sheet to exert bonding process under pressure directed by high frequency dielectric bar

Radio Frequency Bar Welder PVC Fabric RF Welding High Frequency Machine is built-in features of #1: power output variable and control #2: variable pressure at weld #3: welding electrode bar position control #4: press protection #5: RF interference #5: Laser projector in material alignment #6: three sets of emergency stop #7: deep throat of material trough #8: Keder/rode holding guidance

Radio Frequency Bar Welder PVC Fabric RF Welding High Frequency Machine has a wide variety of products that are made with radio frequency welding, also called radio frequency welding, or dielectric welding, some examples would be tensile structures, tents, swimming pool liners, high speed rolling doors, oil booms, billboards, sun shades, insect screen, banner, signs, inflatable products, awing, clear span buildings, athletic mattress, plastic facades, pergolas, conveyor belt, upholstery, protective packages, and air or liquid container/tank/storage/bag

Radio Frequency Bar Welder PVC Fabric RF Welding High Frequency Machine is freestanding type of dielectric bar welding,also can built in moving table for continuous welding, its HF/RF power output has ranges from 5kw to 25kw, in addition, the size of welded steel structure frame, electrode and its holding size, the depth of material trough all are acceptable in customization, if you cannot find your concerns, please consult them with our tech team to verify custom modification prior to order

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com