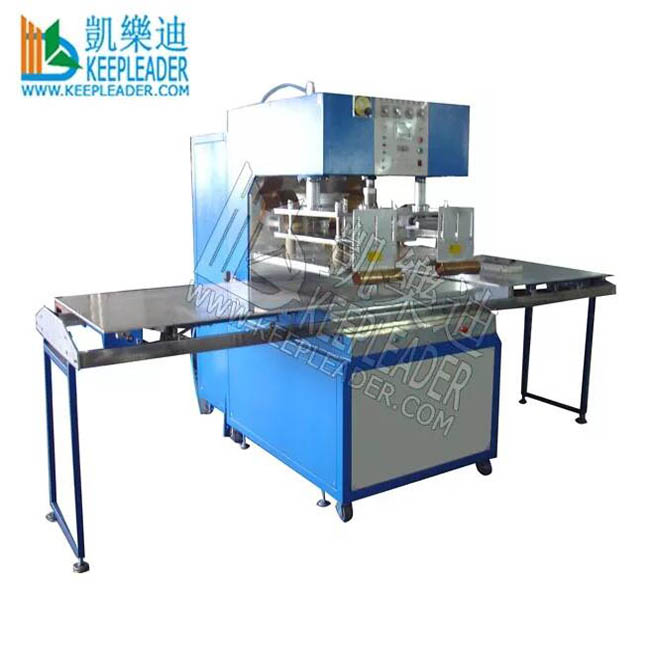

Plastic Welder 8kw Slipway High Frequency Welding Machine

Plastic Welder 8kw Slipway High Frequency Welding Machine

01: Application

Plastic Welder 8kw Slipway High Frequency Welding Machine is especially designed for production of blister packages, but it is multipurpose machine, it also can be used for production process of industrial sealing, embossing, indenting line, such as PU leather cover for pad, automotive parts and car interior elements, soft crease packaging box, safety vests, reflective signs, inflatable toys, cosmetics packing and etc, it is designed for applications requiring precision large flat surface for product positioning and complex shape welds, customization designed tooling and welding upper platen are available on request

The popular application is the seal process of plastic blister packaging, likely seal blister of PVC, PET, PETG,APET; clear blister packaging, plastic clamshell packaging, plastic blister with plastic blister packages, plastic blister with cardboard packages and indenting line of folding box

02:Parameter

| Name | Plastic Welder 8kw Slipway High Frequency Welding Machine | ||

| Model | KLR-5000A | KLR-8000A | KLR-12000A |

| HF Power Output | 5000w | 8000w | 12000w |

| Power Input | 8.5KVA | 15KVA | 18KVA |

| Voltage | AC 220V/380V | ||

| Frequency | 27.12MHz | 27.12MHz | 27.12MHz |

| Operation Mode | Manual slipway alternative feed | ||

| Upper Electrode | 200*350mm | 400*600mm | 450*650mm |

| Lower Electrode | 400*600mm | 600*800mm | 650*750mm |

| Excursion | 150mm | ||

| Oscillation Tube | 7T85RB | 7T69RB | E3130 |

| Heating Temperature | 0~400 degree | ||

| Welding Time | 1~10s | ||

| Weight | 460kgs | 580kgs | 680kgs |

| Dimension | 1200*900*1900mm | 1200*1200*2100mm | 1300*1300*2100mm |

03: Salient Features

Welding length and width can be adjusted, supporting fast changeover welding mold

European-Model square high frequency vibration cavity is more reliable and stable in output

Customized working table dimensions, electrode holder dimensions

High Sensitive anti-spark device to protect the welding mold and sealing material

High Q value tube, strong high frequency power output, stable performance

High Frequency stabilizer and shielding device minimizes HF interference

Manual mould adjusting system provides easiness of operation and interchanging

Four point horizontal adjusting structure is easy and quick for mould balance adjusting

Overflow protection prolongs the tube life span and protect the molds

Cylinder from Taiwan, ensures long lime and high precision movement

Without high frequency leakage because it adopts good shield device

Heating device built in electrode holder to exert melting in auxiliary when applying in PET,PU and etc

Output power tuner takes adjustment according to different material and size in precision setting

Pneumatic pressure design is sufficient in adding pressure

Authorized industrial frequency band of 27.12MHz only has tolerance more or less 0.5%

Molecular bonding produces strong and smooth welding surface without seam

Adopts high quality components, stable and low failure rate and long service time

The machine requires low skill for operation, the operator can use it after short training

Advanced design of self-flow protection system to protect HF tube due to excessive current

Plastic Welder 8kw Slipway High Frequency Welding Machine is stand-along HF welder with Manual slipway in application of sealing process in blister packaging, the basic model of manual feeding welder also can integrate servo-motor driven auto feeding slipway and automatic robotic loading and unloading, slipway tables at two sides of auto ultrasonic welder in alternative feeding material to improve the productivity and reduce the space, interchangeable tooling nests designed to suit specify product process, can be swapped quickly, also can only select one side feeding for flexible production, to ensure consistent quality, and repeatability of welding process, the welder and its tooling incorporate closed circuit temperature control. Alongside this, the power source uses auto-tuning and tracking capabilities to compensate for any material variations during processes, we also offer optional add-on equipment basing on customized demands

Plastic Welder 8kw Slipway High Frequency Welding Machine is manufactured under the supervision of high level team of professionals in the management, engineering and technical cadres, our welders are testing quality on the latest types of testing equipment, confirming to international standards,periodic innovations are very much part of keepleader, we have time and again introduced newer welder and upgraded existing, because we have two regulations to maintains, yours and ours

Plastic Welder 8kw Slipway High Frequency Welding Machine, also know as high frequency bonding, high frequency fusion, high frequency sealing, high frequency lamination, hot melt high frequency, high frequency hot melting, pressing high frequency, high frequency heat sealing, high frequency voltage, high frequency embossing, embossed high frequency, high frequency blister packaging, high frequency mark and etc, can process the following materials, PVC, EVA, PEVA, PET,APET, PETG, GPET, GAG, TPU, PU,PE,MPE and etc thermoplastics, the materials containing the above products include fitting, coating fabrics of these material, textile and synthetic leather materials, and foaming material such as PU foam PVC can be used to process on high frequency welding technology

Plastic Welder 8kw Slipway High Frequency Welding Machine has multi-purpose, is not only applied in blister packaging but also applied in embossing,seam sealing and soft crease line forming, such as to seal blister of PVC,PET,PETG, APET; clear blister packaging; plastic clam-shell packaging; plastic blister with plastic blister packages; plastic blister with cardboard packages; medical are: blood bag, urine bag,IV Bag, colostomy bag, drainage bag, ID wristband etc; automotive: pneumatic lumbar support, fuel and air assembly parts, seat cushion; stationary: covers, albums business cards holders, notebooks, files folder, document pouch; advertising, embossed logo,label, traffic signs; shoes: shoe upper, cover, insoles/pads; universal usage for PVC,PU,TPU reinforced technical textiles

Keepleader is a front runner in the manufacturer of Plastic Welder 8kw Slipway High Frequency Welding Machine, our commitment to deliver quality at economical prices with welder innovations suited to the existing and new end user have helped us to earn market across the world, our state-of-the art works in the heart of our end user clientele, is fitted with latest equipment for manufacture of the machines which confirm to all the relevant specification and technical parameter

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com